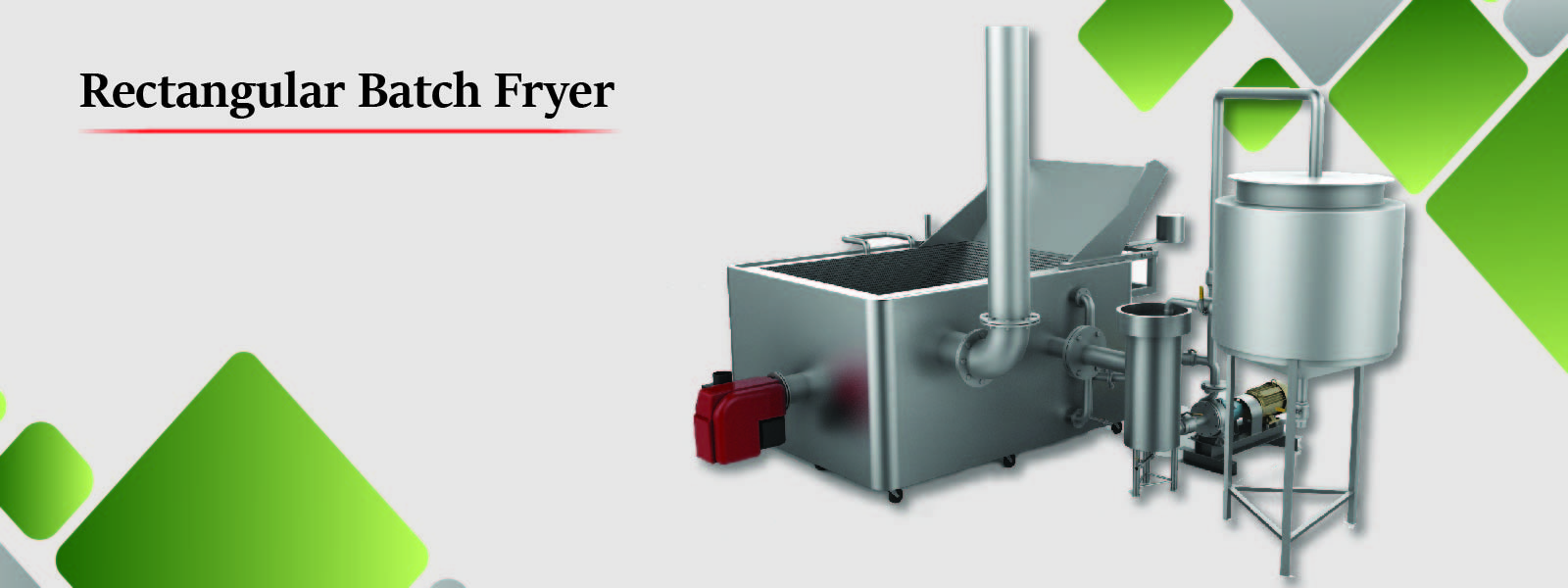

Batch fryer

The Batch Fryer emerges as a key player in the food processing industry. It addresses the demand for efficient and reliable frying solutions. Designed for versatility and precision, this advanced fryer is tailored for batch cooking. This provides a consistent and high-quality frying experience across a variety of food products.

Features

Temperature Control System : The Batch Fryer is equipped with a sophisticated temperature control system. It ensures precise regulation throughout the frying process. This feature is crucial for achieving consistent texture and flavor in fried products.

Adjustable Cooking Time : Offering flexibility in production, the batch fryer allows operators to adjust cooking times. It accommodates different food types and ensures optimal results for each batch.

Efficient Oil Management : Incorporating an efficient oil management system, the fryer minimizes oil wastage and maintains oil quality for extended use.

User-Friendly Interface : The intuitive control panel and user-friendly interface make the Batch Fryer accessible to operators of varying skill levels. This promotes ease of use and reduces the learning curve for efficient operation.

Benefits

Consistent Product Quality : The precise temperature control and adjustable cooking times of the Batch Fryer result in a consistent and uniform product quality.

Increased Productivity : With its batch-cooking capabilities, the fryer enables a continuous and efficient frying process. It contributes to increased production volumes and reduced downtime.

Extended Oil Lifespan : The efficient oil management system enhances the longevity of the frying oil. Moreover, it reduces the frequency of oil changes and associated costs.

Versatility in Food Options : The Batch Fryer accommodates a diverse range of food products. Be it traditional fries and nuggets to speciality items, it allows manufacturers to diversify their product offerings.

Final Words

The Batch Fryer is a marvel in the food processing industry, seamlessly blending precision, efficiency, and user-friendliness to meet the demands of modern frying operations.

Other Products

- Bingo Triangle Cutter

- Two in one Kurkure Puff Corn Extruder Machine

- Pola cutter

- Seasoning machine

- Conveyor

- Kurkure extruder

- Batch fryer

- Oil extractor

- Oil popcorn popper

- Static dryer

- Protein bar extruder

- Energy bar extruder

- Chocolate enrober

- Cooling tunnel

- Vibrator Hopper

- Bhujiya Extruder

- Coating Pan

- Continuous Dryer

- D oiling Conveyor

- Hopper with Screw Feeder

- Material Storage Trolley

- Potato Peeler

- Potato Slicer

- Roaster cum Flavouring Machine

- Peanut Roaster

- Slurry System

- Spice Roaster

- Makhana Grader

- Makhana Powder Making Machine

- Huller Machine (Makhana Cleaning Machine)

- Multimill Pulverizer

- Vibro Shifter

- Tray Oven

- Ribbon Blender

- Popped rice chips making machine